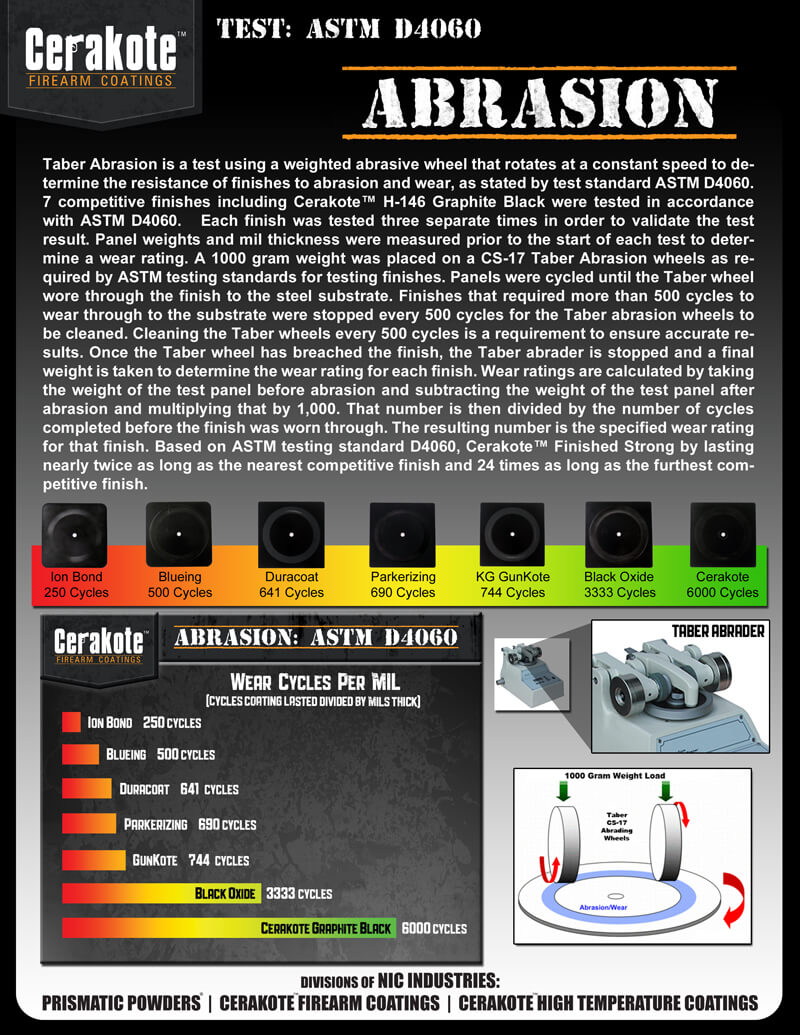

Cerakote gun coatings Abrasion test vs Dura coat, vs Ion bond, vs blueing, vs Parkerizing, vs gun Kote, vs Black Oxide.

TEST: ASTM D4060

Cerakote ABRASION

Taber Abrasion is a test using a weighted abrasive wheel that rotates at a constant speed to determine

the resistance of finishes to abrasion and wear, as stated by test standard ASTM D4060.

7 competitive finishes including Cerakote™ H-146 Graphite Black were tested in accordance

with ASTM D4060. Each finish was tested three separate times in order to validate the test

result. Panel weights and mil thickness were measured prior to the start of each test to determine

a wear rating. A 1000 gram weight was placed on a CS-17 Taber Abrasion wheels as required

by ASTM testing standards for testing finishes. Panels were cycled until the Taber wheel

wore through the finish to the steel substrate. Finishes that required more than 500 cycles to

wear through to the substrate were stopped every 500 cycles for the Taber abrasion wheels to

be cleaned. Cleaning the Taber wheels every 500 cycles is a requirement to ensure accurate results.

Once the Taber wheel has breached the finish, the Taber abrader is stopped and a final

weight is taken to determine the wear rating for each finish. Wear ratings are calculated by taking

the weight of the test panel before abrasion and subtracting the weight of the test panel after

abrasion and multiplying that by 1,000. That number is then divided by the number of cycles

completed before the finish was worn through. The resulting number is the specified wear rating

for that finish. Based on ASTM testing standard D4060, Cerakote™ Finished Strong by lasting

nearly twice as long as the nearest competitive finish and 24 times as long as the furthest competitive

finish.